Quality Assurance Management

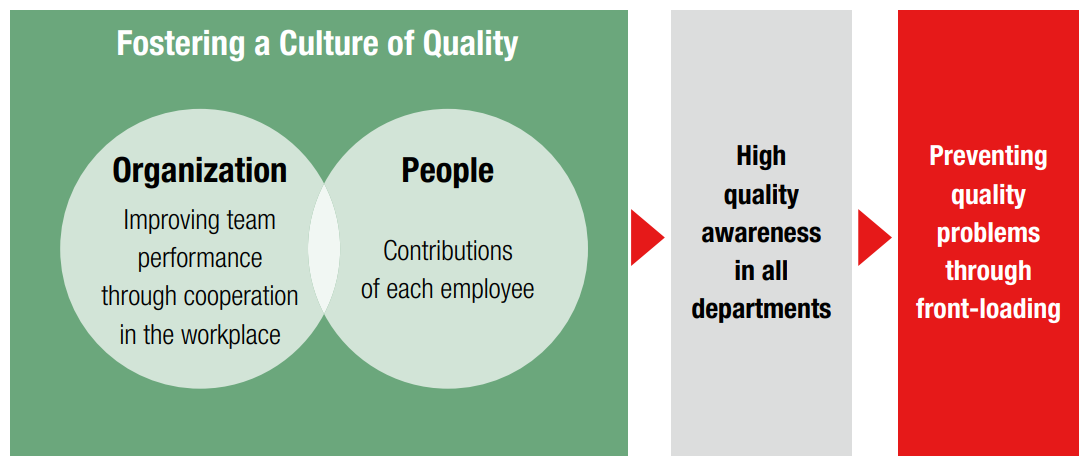

NHK Spring has been working to improve quality and customer satisfaction by listening more closely to customer feedback under the slogan “Quality-first manufacturing”. Moreover, in order to create products that are even safer and more reliable, we are fostering a high level of quality awareness by focusing on “Fostering a culture of quality” and placing importance on “Human resource development” and “Organizational development”. By promoting these initiatives and applying them to “front-loading manufacturing”, we are working to prevent quality issues before they arise, and to further improve customer satisfaction and earn the trust of our stakeholders. We are making tireless efforts to maintain the “reliable quality” that firmly supports NHK Spring's “indispensable key parts”.

Quality Policy

Quality Policy in the 2026 Medium-Term Management Plan

By fostering people development and cultivating a strong corporate culture as our foundation, we strive to achieve globally competitive quality and enhance customer satisfaction worldwide.

FY2025 Priority Measures

(1) We adhere firmly to the principle of BNF (*), openly acknowledging issues together and taking collective action to implement countermeasures.

* Bad News First / Fast ... The principle of promptly sharing problems and adverse news first

(2) Through the organization and analysis of process data, we implement measures with a focus on the quality of subsequent processes.

Fostering a Culture of Quality

We value “Human resource development” and “Organizational development” by increasing the opportunities for each individual to play an active role, creating a rewarding environment, and improving the sense of solidarity within the team. Building on this corporate culture, we are cultivating a high quality awareness in all departments by deepening our understanding of the importance of listening to our customers' opinions, the importance of following the rules, and a sense of responsibility.

Human Resource Development

In addition to general knowledge education covering such topics as statistical processing, NHK Spring's quality-related training also includes content intended to raise awareness of “logical thinking and team discussion,” which leads to “Human resource development.” The training is not only for employees involved in manufacturing and quality control, but also for those in sales, operations, design and development, and is conducted as part of a training program for different levels of staff. Through this training program, we are instilling a strong quality mindset in our employees at all levels and in all areas of the Company.

In addition to group training, we continuously communicate the way of thinking that is required for organizational activities through e-learning, on-demand content, and in-house newsletters. This has fostered quality awareness in not only the quality department but across all departments based on the belief that "quality is created through the participation of everyone”, and this has led to "Creating safe and reliable products".

Organization Building

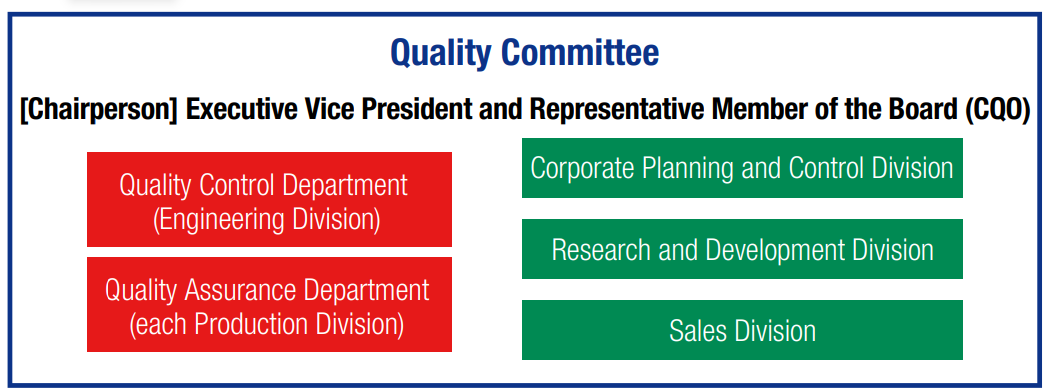

Quality Committee

NHK Spring has established a Quality Committee under the Management Committee. Having the Executive Vice President and Representative Member of the Board & CQO (Chief Quality Officer) as Chairperson, and comprising members from the Quality Control Department of the Head Office Engineering Division, quality assurance departments of each production division, the Corporate Planning and Control Division, the Research and Development Division and the Sales Division, the Quality Committee formulates quality policies for each fiscal year, shares information on quality issues, and discusses the medium- to long-term goals and future direction of initiatives.

The content discussed at the Quality Committee is shared with departments through each production division's quality assurance department, ensuring that the direction of policies and initiatives is shared. In addition, the Quality Management Department at the Head Office conducts quality audits based on this content, as described later.

Responding to Quality Issues

With the slogan “Bad News First (Fast)”, NHK Spring encourages the early launch of countermeasures and the immediate sharing of information with those involved when problems occur, and we always remain highly aware of quality risks.

In cases of particularly important quality issues, reports are made to the CQO and other relevant parties, and discussions on how to respond are held promptly. If an issue is difficult to resolve, a project team is set up with members from across the organization. In this way, a system is in place to quickly and flexibly address quality issues.

Quality Audits

In order to maintain a system for delivering safe and reliable products to our customers, NHK Spring regularly audits the quality control status of plants under the jurisdiction of the quality assurance department of each production division. Moreover, the Quality Control Department at Head Office conducts an “audit of audits” from a third-party perspective, also covering the results of quality audits conducted at each production division. In addition to checking actual sites, actual products, actual situations, and principles, the “audit of audits” also involves interviewing and surveying the people involved, including those in the design and development departments, to check for problems and the status of information sharing within the organization, and to make recommendations for creating a workplace with good communication.

As part of the “audit of audits” activities, we also hold lectures (training) on quality compliance and team building.

Through activities that combine auditing and education, we are working to create an organization where teams can work together to tackle issues.

Manufacturing Innovation Activities

The Engineering Division Production Research Department and each production base work together to promote manufacturing innovation activities. Identifying areas for improvement in manufacturing at production bases from the perspective of quality and productivity, we discuss countermeasures and link them to on-site improvements. By having Head Office and production bases work together, this leads to the creation of a culture where all staff pull together to manufacture products, rather than leaving things to the people on the factory floor.

QC Circles

Since 1965, NHK Spring has continued QC circle activities in small groups using QC methods as a workplace improvement activity based on the creativity and mutual inspiration of employees. At the NHK Spring QC Circle Convention, 13 circles including those from domestic and overseas Group companies participate every year to make presentations, etc. This is an opportunity to hone global and other on-site capabilities, as well as a place where the results of workplace improvements in team capabilities in departments and sections are announced.

1966 First All-NHK QC Effectiveness Case Study Presentation Meeting

2024 President Uemura delivering the opening address

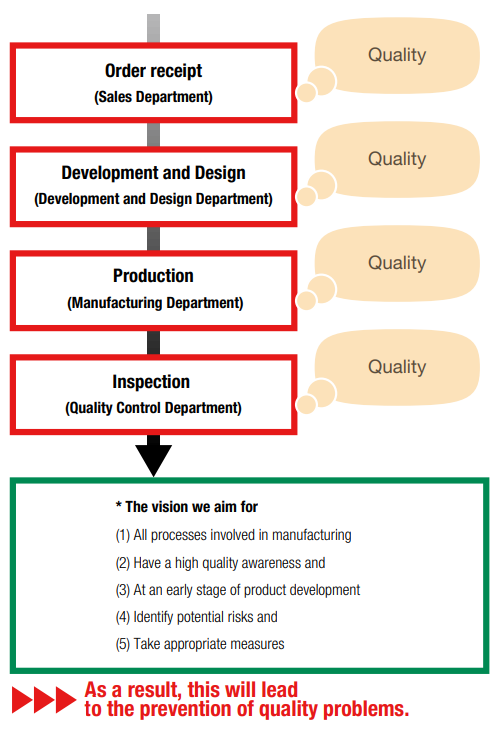

Manufacturing Based on Front-loading

In addition to the idea of building quality into the process, NHK Spring promotes the concept of “front-loading”, which means that all manufacturing processes have a high quality awareness and identify and address potential risks at an early stage of product development. This approach helps to prevent quality problems.

Results of Front-loading Activities (Automotive Seating Business)

The Seating Division of NHK Spring has traditionally faced the following issues: (1) how to work before receiving orders, (2) how to prevent problems in the early stages of mass production, (3) how to improve the efficiency of design staff, and (4) how to train young designers.

To resolve these issues, based on the key phrase “early quality creation through front-loading of work”, we implemented business process reforms in the upstream processes from order receipt to mass production. These included the establishment of processes for discovering and solving quality issues, such as design reviews (DR)*1 and gate management*2, as well as the clarification of the responsibilities and roles of each department (elimination of gray zones) and the reduction of design-related work.

The activities, carried out by a total of 70 members over a period of five years, resulted in streamlining of the workflow from the pre-order stage to the start of mass production, and led to the establishment of a quality awareness from an early stage.

By spreading these good practices across the Group, we are using them to further develop our quality culture and strengthen our systems.

*1 Design Review (DR)…A meeting or review to evaluate and confirm the quality, performance, suitability, etc. of a product at the design stage in the product development process.

*2 Gate management: A management method in which progress is evaluated and a decision as to whether to proceed to the next stage is made at each specific stage (gate) of the product development process.

Customer Evaluations

Some examples of commendations received from customers

FY2022

Domestic

-

Nissan Motor Co., Ltd. Certificate of Appreciation for Outstanding Quality

-

Honda Motor Co., Ltd. Certificate of Appreciation for Excellence (Quality Division)

-

DAIHATSU MOTOR CO., LTD. Quality Excellence Award

-

AISIN CORPORATION Quality Excellence Award

-

JATCO Ltd Regional Quality Award

-

EXEDY Corporation Outstanding Quality Award

Overseas

-

Toyota Motor North America, Inc. Quality Achievement(SEAT)

-

Toyota Kirloskar Motor Ltd. Zero PPM & Quality Certification

-

Honda Cars India Ltd. BRONZE AWARD "NON-CURRENT"

-

JATCO (Guangzhou&Suzhou) Automatic Transmission Ltd. Quality Award

FY2023

Domestic

-

TOYOTA MOTOR CORPORATION TOYOTA GAZOO Racing Company Certificate of Appreciation for Technology and Quality

-

Nissan Motor Co., Ltd. Certificate of Appreciation for Outstanding Quality

-

NISSAN SHATAI CO., LTD. Certificate of Appreciation for Quality Contribution

-

Hino Motors,Ltd. Outstanding Quality Control Award

-

EXEDY Corporation Outstanding Quality Award

Overseas

-

Nissan North America, Inc. Quality Master Certificate

-

Isuzu Engine Manufacturing Co., (Thailand) Ltd. FY2023 QD Awards

-

Hino Motors Manufacturing (Thailand) Ltd. Best Quality Performance, Silver Award

-

JATCO (Guangzhou&Suzhou) Automatic Transmission Ltd. Quality Award

-

Jatco Mexico, S.A. de C.V. Quality Award

-

CHINA FCC FOSHAN CO., LTD. Outstanding Quality Award