Creation of Environmentally Friendly Products

Overview of Environmentally Friendly Products

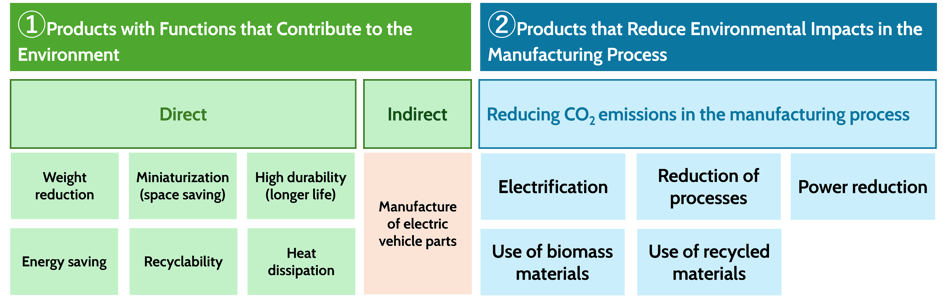

NHK Spring creates environmentally friendly products from two perspectives: "products with functions that contribute to the environment" and "products that reduce environmental impact in the manufacturing process".

①Products with Functions that Contribute to the Environment

[Weight reduction]

Materials development and design innovations

In coil springs and hollow stabilizers used for automobile suspensions, we are pursuing weight reduction while maintaining durability.

By making these products lighter, we contribute to improved fuel efficiency in automobiles and reduced CO₂ emissions, thereby helping to mitigate the impacts of climate change.

For example, in coil springs, weight reduction is achieved through enhanced shot peening, advanced material processing technologies, and the use of high-strength developed steels. In hollow stabilizers, the selective use of thin- and thick-walled tubes enables a 20–50% weight reduction compared with solid types.

[Heat dissipation]

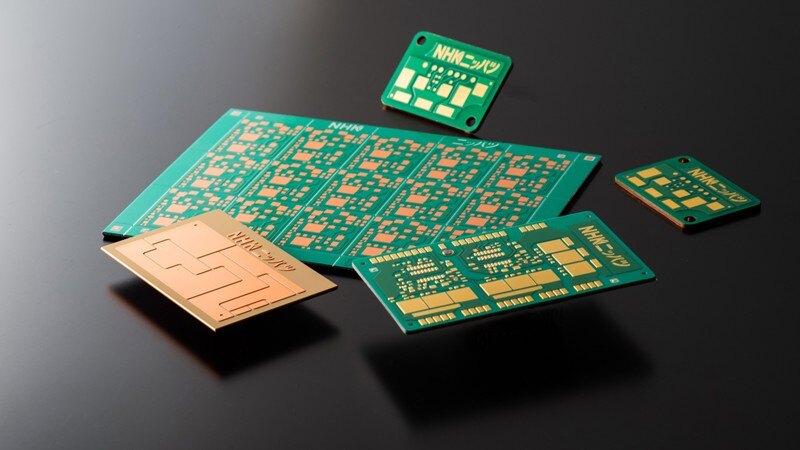

Integrated metal substrates with high heat dissipation

For printed circuit boards, we use aluminum, copper, iron and other metals as the main materials. Leveraging the properties of these metals, these PCBs offer high heat dissipation and are increasingly used in inverters and converters essential for vehicle electrification, as well as in LED headlamps and small motors, with demand continuing to grow.

【Recyclability】

Environmentally friendly concept seats

Conventional automobile seats have a structure in which the cover and urethane are assembled together, making it difficult to separate the components for recycling.

The environmentally friendly concept seat has been redesigned in terms of its covering structure, enabling disassembly in roughly half the time required for conventional seats. In addition, as the materials can be more easily separated at the time of disposal and the cushion pad uses biomass-certified materials, the seat offers enhanced recyclability.

【Manufacture of electric vehicleparts】

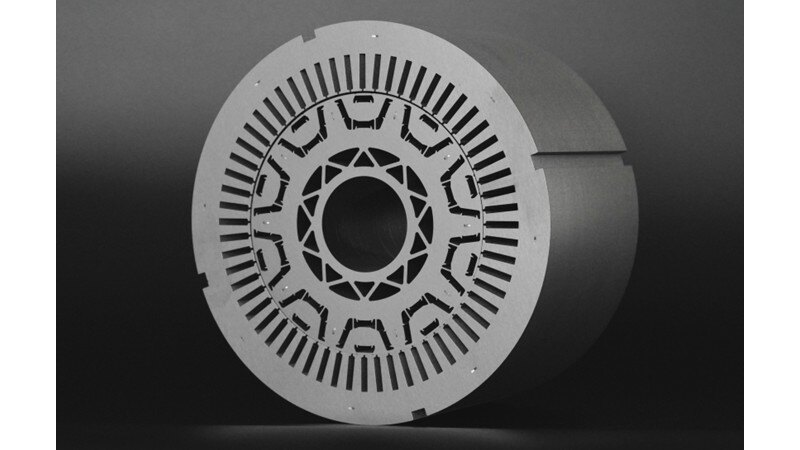

Motor cores

Iron cores, consisting of several hundred laminated electromagnetic steel sheets approximately 0.3 mm thick, generate drive within electric vehicle motors.

Leveraging our advanced press processing technology—which covers everything from die design and manufacturing to maintenance—we meet customer quality requirements and expand adoption, thereby contributing to the advancement of vehicle electrification.

②Products that Reduce Environmental Impacts in the Manufacturing Process

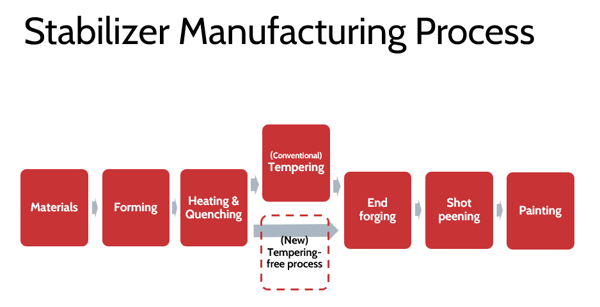

【Reduction of processes】

Simplification of stabilizer tempering processes

Traditionally, the production of solid stabilizers for automobile suspension parts required heat treatment through quenching and tempering. However, by researching, selecting, and applying materials with higher toughness, we have been able to reduce the tempering process, thereby achieving CO₂ reductions.