NHK Spring Group's Environmental Challenges

(Reducing CO₂ and Industrial Waste)

NHK Spring Group's Environmental Challenges

Since publishing the Environmental Voluntary Plan in 1993, the entire NHK Spring Group has been involved in global environmental conservation activities. To further clarify NHK Spring Group's future role in helping to realize a sustainable society, the President & CEO personally declared "NHK Spring Group's Environmental Challenges" in September 2021.

To achieve the goals of "NHK Spring Group's Environmental Challenges", we are promoting initiatives related to our identified material issues of “reducing CO₂ emissions” and “reducing environmentally hazardous substances”.

In line with our medium-term plan through FY2026, each production division is implementing measures to reduce CO₂ emissions and industrial waste. Progress toward achieving the plan is monitored through the Global Environmental Response Committee, which also discusses additional reduction measures. As of FY2024, these initiatives are proceeding on schedule.

NHK Spring Group's Environmental Challenges

① Achieve carbon neutrality by 2039.

To this end, reduce CO₂ emissions by 50% from the FY2013 level by 2030.

② Aim to realize zero industrial waste by 2039.

To this end, reduce industrial waste by 95% compared to FY2013 by 2030.

In March 2025, we also set a target of achieving carbon neutrality (Scope 1 + Scope 2) by 2050, covering NHK Spring as well as both domestic and overseas consolidated subsidiaries.

In FY2025, we will advance preparations for the collection and aggregation of Scope 3 data.

| Item | Emissions | Main Measures Geared to Reduction | Specinic Measures Implemented in 2023 | |

| FY2022 | FY2023 | |||

| CO2 (thousand t-CO2) |

136 | 120 | ・Promotion of energy saving ・Electrification of equipment, fuel conversion, line rearrangement ・Technical innovation in production processes and product development ・Plant investment in solar power generation, etc. ・Purchase of electric power derived from renewable energy |

・Updating of factory lighting equipment ・Electrification of forklifts ・Electrification of equipment, prevention of heat loss ・Improvement of air leaks ・Switching from LPG to LNG ・Updating of air conditioning equipment, etc. |

| Industrial wastes (t) |

71 | 38 | ・Re-examining of recycling contractors ・Promotion of free recycling ・Conversion of waste materials into valuable resources |

・Conversion of waste plastic into valuable resources using material judgment equipment ・Re-verifying sludge recycling companies |

(Note) The above emissions are the total for NHK Spring and consolidated subsidiaries in Japan.

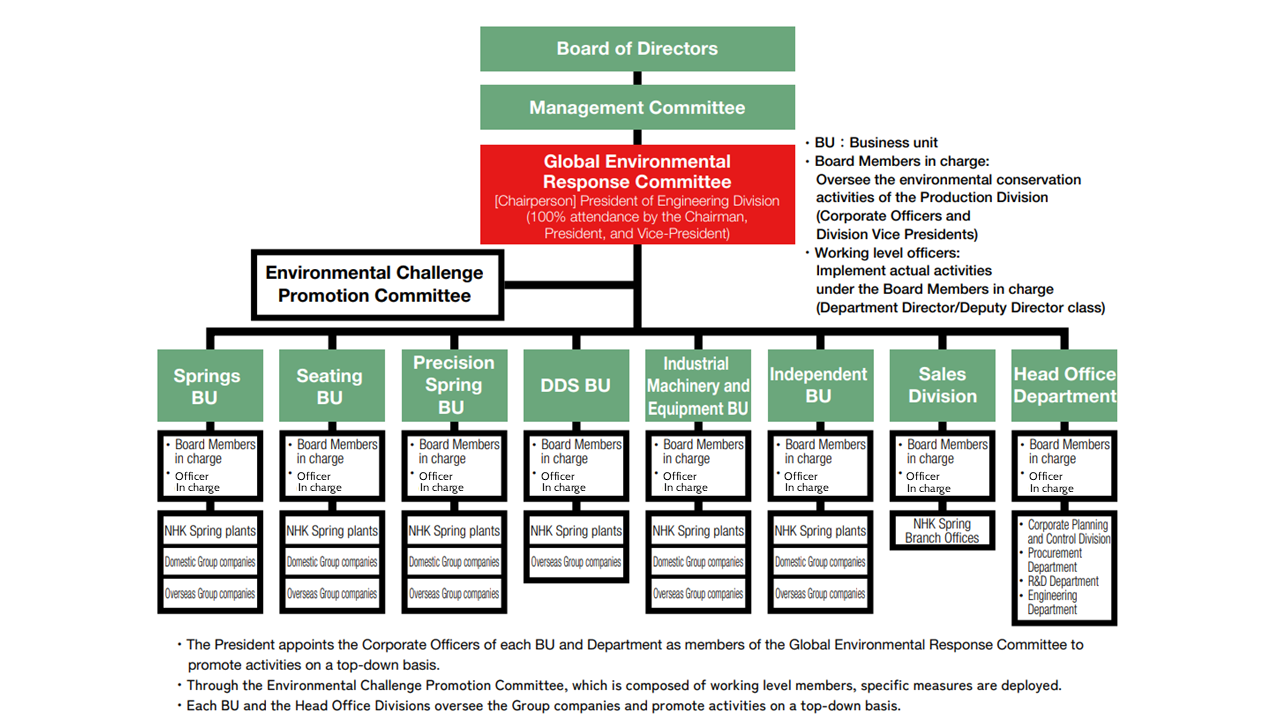

Promotion Structure

Based on the "NHK Spring Group's Environmental Challenges" declaration, the Global Environmental Response Committee has compiled a long-term plan of environmental activities for each business and strengthened activities with a view to realizing a sustainable society in the NHK Spring Group.

The Global Environmental Response Committee meets two times a year. The Committee sets medium- to long-term goals related to the Environmental Challenges, and compiles scenarios and promotes activities geared to realizing them. It periodically reports on the progress of activities to the Management Committee so that they can be reflected in the management strategy.

Reduction of CO₂ emissions

Indicators and Goals

Having set reduction targets for CO₂ emissions calculated according to the amount of energy consumption, NHK Spring Group is committed to implementing global environmental conservation activities.

Aiming to achieve the Environmental Challenges declaration, we have been managing our performance based on total CO₂ emissions since FY2021.

Medium- and Long-term Targets

| Item | Year of achievement |

Target value |

| CO2 Emissions |

2030 | CO2 emissions in SCOPE 1 + SCOPE 2 50% down compared to FY2013 |

| 2039 | Zero CO2 emissions in SCOPE 1 + SCOPE 2 |

* SCOPE 1: Direct emissions of greenhouse gases by business operators (fuel combustion, industrial processes)

* SCOPE 2: Indirect emissions arising in line with use of electricity, heat and steam supplied by other companies

CO₂ Reduction Activities in FY2023

In FY2023, following on from the previous year, we implemented measures such as updating compressors to optimize control, replacing aging air conditioners, electrifying boilers that use fossil fuels, and reducing and discontinuing use of equipment. In addition, we introduced solar power generation facilities and purchased renewable energy. As a result, both the total amount of CO₂ emissions and the CO₂ emissions per unit of sales decreased at NHK Spring and Group companies in Japan.

Transition in CO₂ Emissions and Reduction Targets (NHK Spring + Domestic Group Companies)

Utilizing Renewable Energy - Amount of Solar Power Generated

NHK Spring Group is promoting the introduction of solar power generation equipment with the aim of switching to non-fossil energy. To date, we have introduced solar power generation equipment at 5 NHK Spring factories and 15 Group companies in Japan, for a total of 20 business sites.

In order to achieve carbon neutrality, we are currently planning to introduce and expand solar power generation facilities at multiple business sites.

Fostering a Corporate Culture Geared to Achieving Carbon Neutrality

1. Carbon Neutrality Contribution Award

In order to share the technological measures being taken to achieve carbon neutrality across the entire Group, we are giving awards to recognize cases of CO₂ emissions reduction.

In 2023, there were 29 entries from NHK Spring and domestic Group companies, and the President's Award was presented to the NHK Spring Seating Division Gunma Plant for “Improvement of steam energy conservation in the seat finishing process”.

Outline of “Improvement of steam energy conservation in the seat finishing process”: In the process of removing wrinkles from seats using a steam iron, steam was previously released constantly for safety, quality and productivity reasons, however, by changing the equipment so that steam is only released when necessary, it has been possible to improve steam energy conservation in the process.

2. Strengthening monitoring using environmental website

The Safety and Environmental Activities Dept. has set up an environmental website on the NHK Spring intranet. This site makes it possible to check energy consumption and CO₂ emissions in the Company and domestic Group companies. The Safety and Environmental Activities Dept. monitors trends in emissions through the website and conducts monthly follow-ups on facilities that are lagging behind.

Carbon Neutral Plant

The Miyada Plant, which manufactures semiconductor process components, achieved carbon neutrality (CN) in April 2025. Established in April 2019 as a new facility, the plant was designed and built from the outset with the concept of being carbon-neutral, operating without the use of fossil fuels. CO₂ emissions are tracked not only from the production floor but also from heating equipment and the cafeteria. By fully electrifying all equipment within the plant, fossil fuel–derived CO₂ emissions have been eliminated. Through the purchase of renewable energy and the introduction of solar power generation, the plant contributes to reducing approximately 4,000 t-CO₂ annually. Solar panels were installed from the time of its establishment, and were also added to the new production building completed in 2024. This fiscal year, additional panels will be installed in available spaces of existing buildings.

Carbon Neutral Investment

NHK Spring, under the NHK Spring Group’s Environmental Challenges, is working toward achieving carbon neutrality by 2039, with a focus on the development of new technologies. Specifically, as part of our carbon neutrality investments, we plan to allocate 10 billion yen through FY2026 in line with our medium-term plan to promote initiatives such as the electrification of production facilities and the purchase of renewable energy.

Reduction of environmentally hazardous substances

Industrial Waste Reduction Targets (NHK Spring Group's Environmental Challenges)

| Management item | Target year | Contents |

| Amount of non-recyclable wastes |

2030 | Reduce emissions by 95% compared to FY2013. |

| 2039 | Aim for zero emissions |

NHK Spring and its domestic Group companies are working to reduce industrial waste as part of our global environmental conservation activities, and we have achieved our group target of a “recycling rate of 99% or more” every year. Furthermore, in accordance with the industrial waste targets set out in the “NHK Spring Group's Environmental Challenges” declaration of September 2021, we will work to achieve even stricter targets for reducing the amount of non-recyclable wastes*.

At present, we define thermal recycling as a resource recovery process, however, because CO₂ is generated during incineration, we are considering switching to material or chemical recycling in the future.

*Non-recyclable wastes = industrial wastes that are not reused and recycled due to landfilling or otherwise

FY2023 Reduction Results and Future Reduction Plans

In FY2023, we reduced industrial waste emissions by 68% compared to the FY2013 level, achieving our reduction target. We will continue to work on waste reduction activities in order to achieve the goals set out in NHK Spring Group's Environmental Challenges.

Concrete Initiatives (Examples)

We introduce some of the initiatives that NHK Spring and domestic Group companies are implementing to achieve NHK Spring Group's Environmental Challenges. The following are the main activities for reducing non-recyclable wastes.

(1) Thorough sorting and conversion of waste plastic into valuable resources using material judgment equipment

(2) Re-examining of recycling contractors capable of conducting recycling

(3) Promotion of free recycling and conversion of waste materials into valuable resources

Case ① Reduction of non-recyclable wastes through a review of industrial waste disposal methods (NHK Seating Mizushima)

Because some of the waste plastic discharged from the factory was treated as mixed plastic, it was previously disposed of by landfilling as non-recyclable waste, however, by improving the sorting process and conducting recycling, it has been possible to change all of it to recycled materials.

| Result Reduction of non-recyclable wastes by 3.0t per year |

Case ② Converting waste plastic into valuable resources and material recycling (NHK FLEX)

Previously, the plant carried out thermal recycling of waste materials generated in the extrusion molding process, however, by sorting the waste plastic by type and reviewing the processing subcontractor, it has been possible to convert wastes into valuable resources and achieve material recycling.

| Results Conversion of 8.3t of waste plastics into valuable resources, and revision of conventional thermal recycling to material recycling |